AP Global R&T Centre - Leaping towards New Era

Journey of Asian Paints Global business started in the year of 1978 through joint venture in Fiji market. Down the line global business has extended across globe viz. South Asia, South Asia Pacific, Middle east and African continent. Currently AP Global R&T center is present in Nepal, Bangladesh, Sri Lanka, Indonesia, Fiji, Egypt, Ethiopia, UAE, Oman, Bahrain and Qatar. Technology centers are enriched with 75 plus qualified scientist having diverse culture and domain expertise. Technology excellence is evenly distributed in all category of coating segments viz decorative, protective, OEM and waterproofing/construction chemical. AP Global is committed to demonstrate product stewardship.

Technology AP Global

The major focus of the technology AP global has been to create unprecedented value for the customer… Customer first !! below are the key focus areas in light of creating value for the customers

Product quality and delivery: Creating the products with best in the class technology solutions to address all the customer needs, special attention to product robustness with appropriate quality plans, demonstration of the product features and customer education for the appropriate and safe use.

Addressing the complaints: We encourage the customers to raise the customers if any and go deeper into the technical aspects of the complaints and have due plans to address from the root

Following are the major initiative for creating product enhancement

Strengthen Exterior portfolio with warranty performance across all impacting properties.

Creating health conscious interior performance products which can provide a whole new hygiene environment for the required.

Giving total painting solution by adding the smart care range of products to address waterproofing needs and the issue related to seepage and leakage in consumer houses

Following the Green and sustainability principles in product design to take care of all the chain members across the product life cycle.

Product Excellence

AP Global has raised the bar of technology by developing new products using path-breaking technology. Newly developed products are suitable across all the geography varying in weather condition and application practices. Various application practices are getting captured through robust U&A (Usage and Attitude study of painter and consumer) market study. This includes high humid tropical region like Indonesia, Sri Lanka, and Bangladesh to regions having high UV index like Indonesia, Oman, UAE to region having extremely low temperature like Nepal. The application practices are diverse owing to local market practices and preference of painters/ contractors.

BU Focus on products

Across AP Global, a major drive was taken to strengthen top coat premium and ultra premium emulsion category (Royale, Apcolite, Select, Acrycoat, Apex, Weathercoat, Ultima……) both for interior and exterior. We are focusing more on color fidelity – offering close to 1800 shades across product category. Exterior and Interior product portfolio are strengthening with warranty document supported by extensive filed validation lab data as well as affiliated with high credential International standard certificates (Vinci Lab UK, SGS Singapore, WIMPI Dubai etc.

Waterproofing became the key agenda across AP Global specially Waterproofing Emulsion and cementitious product (capable to attribute both positive and negative water proofing), Ad Mixture, Repair polymer, Water proofing membrane and Sealants. New products are being launched in South Asia (Nepal, Bangladesh, Srilanka), Middle East (UAE, Oman), Indonesia and Egypt.

Luxury/Premium Emulsion category

This category typically offering promise to safe home Décor exterior as well as Interior…

Royale Health Shield (Bangladesh) / Royale Health safe (Nepal)/ Royale Atmos (Middle East):

Country’s first anti-bacterial paint having Ag ion technology (3 years bacteria killing warranty), Air purifying technology with ultimate stain resistance performance through oleophobic and hydrophobic balance. Product can demonstrate 2 hours contact killing ability with performance of 99.9% (out of 15 bacteria, 13 are passing 99.99%) certified by TUV center.

High Durable Exterior Emulsion Paint :

Ultima, Ultima Protek (Nepal, Bangladesh, Sri Lanka) Weathercoat Family (Middle East and Egypt) with 7 to 10 years warranty promise.

Premium Exterior Emulsion category:

High durable Acrylic and Nano Emulsion Technology based topcoat having high DPUR, light fastness with 1800 color promise (Tuff – Oman/UAE/Bahrain, Apex – Indonesia/Bangladesh/Nepal/Sri Lanka, Weathercoat Classic – Egypt etc.)

Strong exterior product portfolio often leads to business contract from prestigious Govt./military projects, big villas and housing complexes from reputed builders and architects.

Premium Interior Emulsion category:

Unmatched wash ability, hiding achievement by using transfer efficiency technology, whiteness, color accuracy and chemical resistance Emulsion system - Apcolite (Oman/UAE/Nepal), Acrycoat Emulsion (Egypt), TE – Bangladesh/Indonesia etc.

Apcolite Product launch in Oman:

PD Free Enamel Paint

All the 11 countries are offering PD free enamel paint with unmatched hiding, drying and hardness attribute with anti-yellowing performance warranty and superior finish.

Waterproofing Portfolio Enhancement:

Across AP Global has committed to establish strong waterproofing product portfolio in the area of waterproofing emulsion (sealer and emulsion topcoat), repair polymer, ad mixture, membranes and sealants etc.

Damp proof Ultra and Dampblock 2K (Indonesia) and Damp Proof Spark (Nepal):

Key Features of Damp Proof Ultra:

Warranty: Performance warranty of 12 years, which includes 12 years film integrity, 7 years waterproofing and 5 years anti-algal.

High elongation with high tensile strength: Combination of Acrylic - Styrene acrylic and Poly Urethane dispersion with Silicone – Ceramic resulting in high elongation with high tensile strength.

Other properties – Resist up to 10 bars of positive hydrostatic pressure, Crack bridging upto 2.5 mm, Anti-carbonation, Good resistance to chloride ion diffusion,

Colors available – 1200+;

Key Features of Damp Block 2K:

Waterproofing both positive and negative side of waterproofing. Resist up to 5 bars of positive hydrostatic pressure, Anti Efflorescence and Anti-Carbonation.

Other important areas in waterproofing segment is also being covered like repair polymer, ad mixtures and waterproofing membranes.

PC Products

Middle East (UAE, Oman and Bahrain) is considered strong player in PC market. Company has entire range of products light industrial, OEM, floor coating and PC. Maximum products have Third party certificates from renowned lab like Shell, Cot B.V. etc

Wood Coating

AP Global has strong presence in Wood coating segment in terms of offering NC to PU range with unmatched performance and superior finish. Asian Paints Oman is one of the pioneers in wood finish and is preferred supplier in most of the joineries across the country. It has a complete range of Clear and pigmented products for wood and allied surfaces- Acrylic PU, Acid cured, Nitrocellulose and 3-4 range of dye based stains. Recently Asian Oman indigenously developed - Flame retardant lacquer- meeting the specifications of BS 476, Part-6 and ASTM E-84 for wooden and allied surfaces.

Sri Lanka, Fiji, Bahrain and Dubai also has similar strong product portfolio in this category.

OEM and Car Refinish segments

AP Global has very strong presence in OEM and car refinish segment in Sri Lanka and Fiji.

Consumer Touch Point

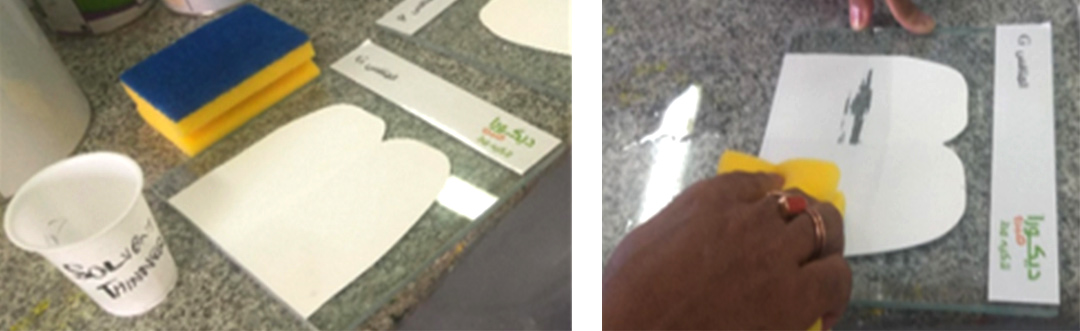

To improve the consumer touch point, development and demonstration of demo tool became DNA of technology center. These demo tools are capable to demonstrate USP of the product convincingly to the end consumer/dealer/contractor/painter. All the new launches were comprised of demo tool in terms of live demonstration or third party certificates.

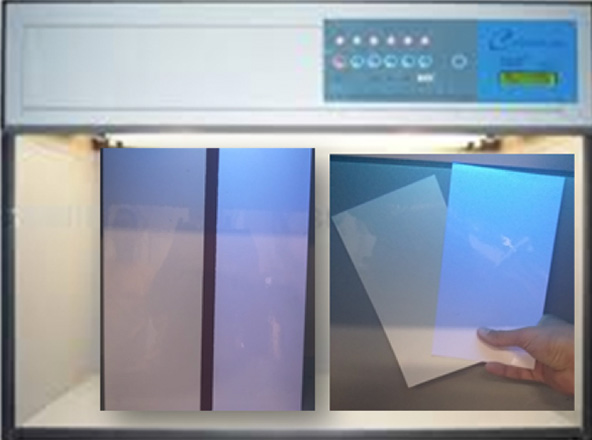

Whiteness Test in UV light against competition…(Left side competition and right side AP Global – bright white)

Demo Tool for Acrycoat Family

Dealer Launch

Lab Hygiene and People Engagement:

Safe work practices are followed in laboratory by using proper PPEs, providing suitable infrastructure to work, following instruction as mentioned in MSDS while handling any new RM, strong adherence to EHS policy and 5 S practices.

Employee success/accomplishment are usually celebrated through nominating and acknowledging through ROTS.

International Teams

Bangladesh

Asian Paints Bangladesh works on developing new products like creating new shades for different products as well as customising shades based on client requirements. Product improvement and upgrading are carried out here.

Bahrain

Berger Paints Bahrain (BPB) is one of the overseas subsidiaries of Asian Paints India. It is an ISO 9001, 14001 certified paint company, and a major market share of decorative and industrial products on the island.

Egypt

SCIB Chemicals S.A.E. is an ISO 9001 and ISO 14001 certified paint manufacturing company in Egypt. The team is focused on the development of all kinds of architectural paints, wood coatings, and industrial/PC products as per local requirements.

Emirates

Berger Paints Emirates Limited is an ISO 9001 and ISO 14001 certified paint manufacturer involved in the development of decorative, wood, and industrial/protective coatings as per the requirements of the GCC region and the local UAE market.

Ethiopia

Kadisco Paints and Adhesive Industry S.C. is one of the oldest paint and adhesive manufacturing companies in Ethiopia. It works on the development of decorative paints, automotive paints, industrial paints, wood paints, and adhesives.

Fiji

Asian Paints (SP) Ltd., Fiji, has a central technology department for the South Pacific region. It is the only laboratory in the South Pacific with National Association of Testing Authority (NATA) accreditation for testing requirements compliant to ISO/IEC 17025. It also has successfully developed 90 products that are Australian Paints Approval Scheme (APAS) approved.

Sri Lanka

Asian Paints Sri Lanka focuses on product development and improvement, cost reduction, benchmarking, complaint management, and localising products. The unit is responsible for launching a variety of waterproofing primers, and solvent-based wood stains and varnishes

Nepal

Asian Paints Nepal focuses on alternate vendor development, fine-tuning shades, incorporating feedback to further develop formulations, and customer complaint resolution along with ensuring hygienic working conditions.

Oman

The Asian Paints Oman team focuses on developing and modifying products for the region. Their focus is mainly on raw material substitution and replication/localisation of regional products.

Know more about what we do